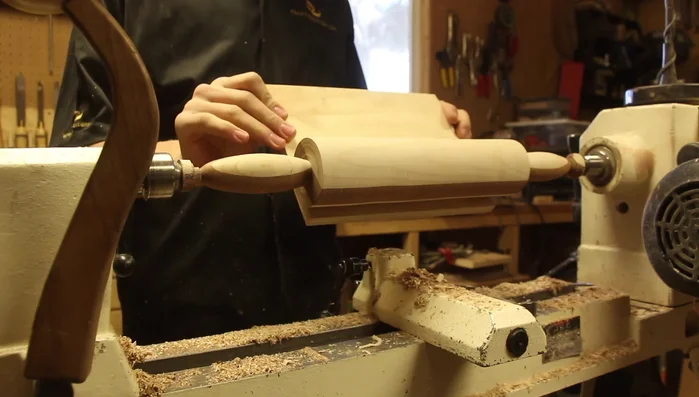

The humble rolling pin: a kitchen essential, often overlooked for its simple design. But what if you could craft your own, transforming a piece of wood into a personalized, beautifully functional tool? This beginner's guide to woodturning will walk you through the process of creating a stunning DIY rolling pin, from selecting the right wood to achieving a perfectly smooth, polished finish. Forget mass-produced kitchenware; discover the satisfaction of creating something unique and durable with your own two hands.

Woodturning might seem intimidating, but crafting a rolling pin is a surprisingly accessible project, even for complete novices. This guide will break down each step, providing clear instructions and helpful tips to ensure your success. Ready to get started and transform a block of wood into a beautiful and practical rolling pin? Let's dive into the step-by-step process!

Preparation and Safety Guidelines

- Rolling pin blank

- Lathe

- Spindle roughing gouge

- Parting tool

- Calipers

- Sandpaper

- Plywood

- Small bowl gouge

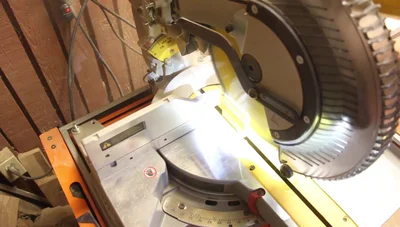

- Hand saw

- 3/8 spindle gouge

- Walnut oil

- Always wear appropriate safety glasses and a dust mask. Woodturning produces flying chips and dust that can cause serious eye and respiratory injuries.

- Keep your hands and fingers away from the cutting tool and workpiece, especially when the lathe is running. Use push sticks or other tools to help manipulate the wood whenever possible.

- Ensure the wood is securely mounted in the lathe before turning. Loose or improperly mounted wood can cause it to fly off and cause injury.

Step-by-Step Instructions

Prepare the Blank

- Glue and cut the rolling pin blank to the desired length.

- Mount the blank on the lathe.

Prepare the Blank Initial Shaping

- Use a spindle roughing gouge to remove the corners and shape the blank.

Initial Shaping Establish Dimensions

- Use calipers to mark the desired size along the blank.

- Use a parting tool to remove flat spots.

Establish Dimensions Shape Handles

- Mark out the handle positions and lengths.

- Shape the handles using tools.

Shape Handles Surface Flattening

- Sand the rolling pin using sandpaper on plywood to ensure a flat surface.

Surface Flattening Refine Shape and Corners

- Round the corners using a small bowl gouge.

Refine Shape and Corners Sanding

- Sand the entire surface with various grits of sandpaper.

Sanding Finish Ends

- Reduce the ends of the rolling pin as thinly as possible without breaking off the lathe, then cut them off with a handsaw and sand them smooth.

Finish Ends Finishing

- Apply walnut oil to finish.

Finishing

Read more: DIY French Rolling Pin: A Beginner's Wood Lathe Project

Tips

- When sanding with a block, use the entire surface to avoid uneven removal of material.

- When sanding with rougher grit sandpaper, be less aggressive to avoid divots.