Tired of unevenly rolled dough and aching wrists? Imagine a rolling pin that effortlessly glides across your pastry, ensuring perfectly consistent thickness every time. This isn't just a dream; it's the reality you can create with this DIY rotating handle rolling pin. This woodturning masterclass guides you through the process of crafting a beautiful and functional rolling pin, transforming a simple kitchen tool into a piece of handcrafted artistry. We’ll explore the techniques necessary to shape the rolling pin body, create the ingenious rotating handles, and achieve a flawless, food-safe finish.

Forget mass-produced kitchenware – embrace the satisfaction of building something truly unique and personal. This project is perfect for woodturners of intermediate skill level, offering a rewarding challenge and a chance to showcase your skills. From selecting the right wood to final sanding and oiling, we’ll cover every detail. Ready to get started? Let's dive into the step-by-step instructions and transform your woodworking passion into a practical, elegant rolling pin.

Safety Guidelines

- Always wear appropriate safety glasses and a dust mask when using woodworking tools, especially during sanding and finishing.

- Ensure the lathe is securely fastened and running at a safe speed for the wood you are using. Never reach over or across a moving lathe.

- Use sharp tools and maintain a firm grip. Woodturning requires focus and concentration to prevent injury from spinning wood or flying debris.

Methods: Creating a Rolling Pin with Rotating Handles

Tools Needed

- Lathe

- Wood Blanks (Maple or similar)

- Cherry Wood for Handles

- Dowel (1/2 inch)

- Wood Glue

- Sandpaper (up to 320 grit)

- Mineral Oil

- Super Glue (for filling gaps)

Step-by-Step Instructions

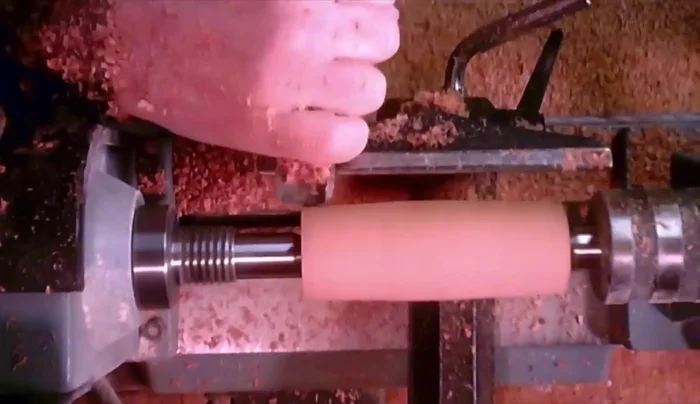

Prepare Main Rolling Pin Blank

- Prepare the main rolling pin blank. Cut off corners and shape into a rough cylinder on the lathe (around 1250 RPM).

Prepare Main Rolling Pin Blank Refine Rolling Pin Cylinder

- Refine the cylinder, making it perfectly round and smooth. Sand up to 320 grit.

Refine Rolling Pin Cylinder Prepare Handles

- Prepare the handles. Turn the cherry wood blanks into handle shapes on the lathe.

Prepare Handles Repair Handles

- Fill any gaps or imperfections in the handles with super glue, let it harden, then sand smooth.

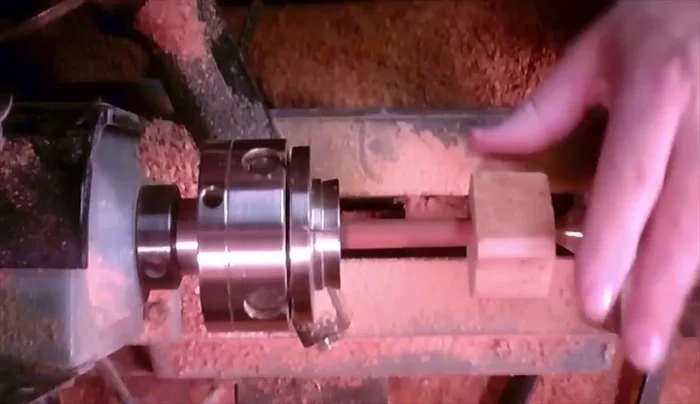

Repair Handles Prepare Dowel Pins

- Prepare the dowel pins for the handles. Cut a dowel to the appropriate length. Glue a block of wood to one end, and then turn this end on the lathe to create a knob.

Prepare Dowel Pins Shape Dowel Pin Knobs

- Mount the dowel pins in the lathe chuck. Turn them down to create the handle knobs.

Shape Dowel Pin Knobs Assemble Rolling Pin

- Assemble the rolling pin. Apply glue to the ends of the dowel pins and insert them into the main cylinder, leaving a small gap for rotation. Apply wax for lubrication.

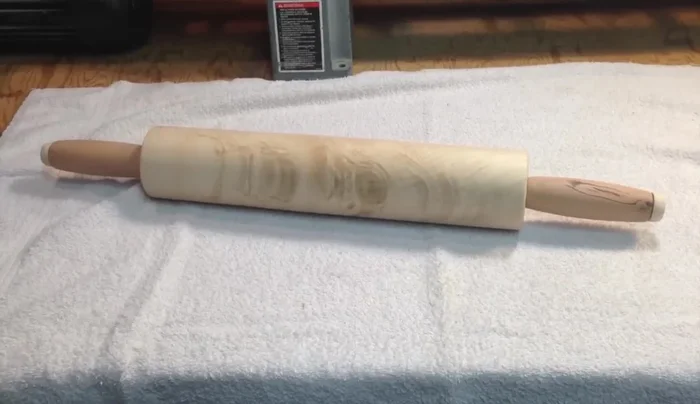

Assemble Rolling Pin Finish Rolling Pin

- Finish the rolling pin. Apply mineral oil as a finish.

Finish Rolling Pin

Tips

- Use a slower lathe speed (around 1250 RPM) for better control when shaping the rolling pin.

- Apply wax to the dowel pins before gluing them into the main cylinder for smoother rotation.

- Finish the rolling pin with mineral oil, just like a cutting board.